We’ve got you covered by partnering with you to ensure no items are overlooked or misidentified. This eliminates the stress in searching for missing parts.

Following are some great tips on how to mark your items for identification.

Remember the most important considerations in identification markings:

- The identification must be made so as to be legible after galvanizing.

- The markings must not disrupt the integrity of the zinc coating and compromise the rustproofing.

For example: Oil-based paints, oil-based markers, or crayon markers will not come off in the cleaning solution used to prepare items for galvanizing. These types of markings may create ungalvanized areas.

For temporary identification, use water-soluble markers or detachable metal tags.

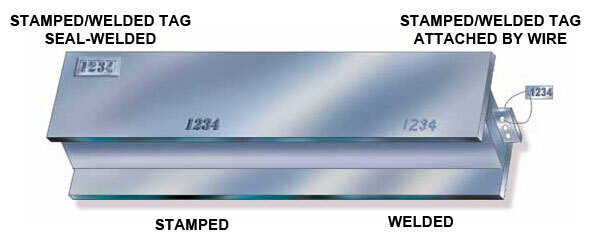

For permanent identification, there are three methods that enable items to be rapidly identified at the job site after galvanizing:

Rapid Identification of Galvanized Products

1. Stamp the surface

Create identification marks by using die-cut deep stencils or by making a series of center punch- marks. These marks should be placed in a standard position on each of the items, preferably toward the center.

The marking must be a minimum of 1/2″ (13 mm) high and 1/32″ (.8 mm) deep to ensure readability after galvanizing.

Important: Do not use this method to mark fracture-critical members.

2. Use a series of weld beads

Letters or numbers can be made directly on the items using this method.

Important: All welding flux must be removed after welding or it will interfere with proper galvanizing.

3. Attach deep-stenciled steel tags

Tags should be wired loosely to the items so that the area beneath the wire will not freeze to the items when the molten zinc solidifies. Or, if you prefer, tags may be seal-welded directly to the materials.

Important: Tags must be a minimum of #12 gauge, and the attaching wire must be a minimum of #9 gauge steel wire.

South Atlantic is capable of providing Kettle Tags, please inquire for availability and more information.

By working together, we go the extra mile to ensure your products arrive as you expect: on time and within budget. There’s no need to worry when you’re working with South Atlantic.